No products

Prices are tax included

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

View larger

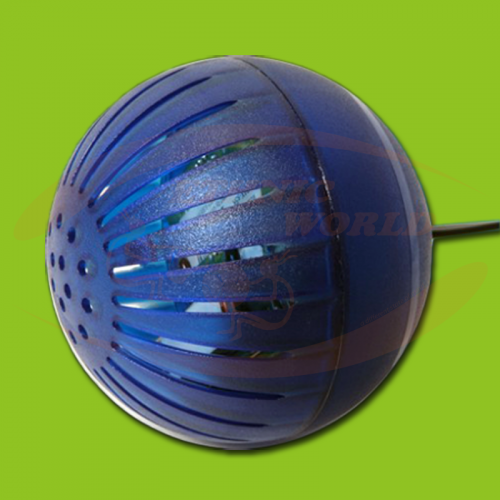

View larger

Pure Factory CO2 pressure regulator + solenoid valve

2 Items in stock

Warning: Last items in stock!

Pure Factory CO2 pressure regulator + solenoid valve.

Description:

- CO2 pressure regulator:

- Pressure regulation: Transforms the high pressure of CO2 (typically between 50 and 60 bars in the bottle) into a low and controlled pressure (typically between 0.5 and 3 bars) for safe diffusion.

- Adjustment wheel: A wheel or adjustment screw allows you to set the desired pressure, making it easier to control the diffusion of CO2.

- Solenoid valve:

- Automation of CO2 flow: The solenoid valve, connected to the pressure regulator, allows the CO2 flow to be controlled automatically. Connected to a programmer or CO2 controller, it opens and closes the passage according to an electrical signal.

- Diffusion control: Perfect for diffusing CO2 only during lighting hours, when plants are photosynthesizing, thus avoiding any waste.

- Reliability and Safety: The solenoid valve is designed to adapt to pressure variations, providing stable and safe operation even over long periods.

Use in horticulture:

Optimization of growth: In horticulture, the addition of CO2 is particularly effective in closed greenhouses or indoor growing spaces, as it allows the CO2 level to be increased (ideally between 1000 and 1500 ppm) compared to natural levels, which are around 400 ppm.

Improved Photosynthesis: A controlled supply of CO2 promotes photosynthesis, increasing the production of sugars and energy for plants, resulting in faster growth and higher yields.

Automated Management: Coupled with a CO2 controller (which continuously measures the level of carbon dioxide in the air), the pressure regulator with solenoid valve ensures that the CO2 level always remains optimal without manual intervention.

Operation:

- Installing the pressure regulator:

- Firmly attach the pressure regulator to the CO2 cylinder, ensuring that the connection is tight.

- Check the pressure gauges to ensure that there is sufficient CO2 in the bottle.

- Pressure adjustment:

- Adjust the output pressure according to the needs of the greenhouse or growing space.

- The recommended pressure for CO2 diffusion in growing spaces is generally 1 to 2 bars.

- Connecting the solenoid valve:

- Connect the solenoid valve to a timer or a CO2 controller.

- Program the solenoid valve to open only during light periods (as plants do not use CO2 at night).

- If connected to a CO2 controller, it will automatically trigger the solenoid valve to open when the CO2 level drops below the desired threshold.

- Diffusion in the growing area:

- Install a CO2 diffuser or distribution system (eg. : perforated pipes or diffusion ramps) to evenly disperse the gas around the plants.

- Ensure that the ventilation system is optimized to not evacuate the CO2 too quickly while maintaining a uniform rate throughout the greenhouse.

Advantages of the CO2 pressure regulator with solenoid valve in horticulture:

Precise Control: Allows you to adjust and maintain an optimal CO2 level continuously, which is crucial for maximizing plant growth.

Automation: The solenoid valve can be programmed to operate only during lighting hours, avoiding CO2 waste.

Safety and Reliability: The man